This is for an overcoat, something with thick layers of fabric. You can skip the raising and wrapping the thread around underneath for a shirt.

I was following along quite nicely until step 9, where you bank-shot the needle off Mars and simultaneously looped it under the button.

I think the toothpick or whatever is to put space while keeping the thread tight? So that when you lift the button everything is still tight and all you have to do is wrap under. The drawing is… not clear.

Oh man I thought that was the needle, not a toothpick. Suddenly this makes sense.

The toothpick is to provide spacing for the button, then you pull it out as you wrap the thread around underneath it.

Hah, this reminds me of when I had to write repair manuals in college. I’d get so fixated on a particular tool, like a toothpick. I’d start by saying, “I’m definitely going to need this toothpick.”

by the end I probably didn’t even need it, but I included it anyway.

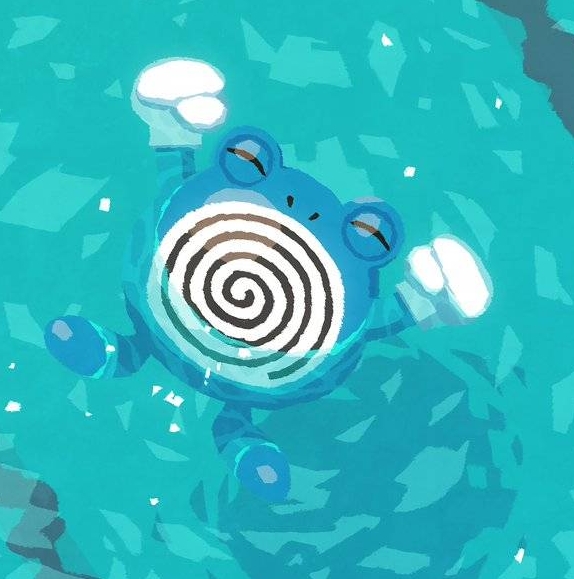

Yes, basically you want (because this is from a jeans company) to create a shank under the button, lifting it enough to fit thick fabric, but evenly so the button sits flat on top!

“You can’t just sew a button onto the surface of mars” - Samuel Hayden

18 steps? What am I, unemployed?

Not anymore. You can be a tailor’s apprentice with this knowledge

Time to engage in sartorial pursuits!

Nah just shove it through in random patterns like a hundred times. It works well enough.

This is the way

I’m sorry but this is way too complicated for what it is. I don’t care about logistics, this is a thing that should be able to be done in 8 steps instead of 18.

That is significantly more complicated than how I was taught to sew in a button. Is this just for big metal buttons on jeans or something? It seems massively over the top for normal shirt buttons, which come off fairly regularly.

Roughly what I was taught (for a 4 hole button, in a “cross” shape):

- Shove threaded needle through material into hole in button

- Go across diagonally and go down through the opposite hole and through the material

- Under the material, go across sideways a bit and come up in a different hole

- Repeat 1-3 a bunch of times until it feels strong enough.

- Tie off the thread and cut off the excess.

The part about wrapping around the treads between the button and shirt is to give space for the button hole side and to protect the threads from wearing against the button hole and provide longevity to the repair.

Yeah, it totally makes sense for some uses.

normal shirt buttons, which come off fairly regularly.

Maybe your technique isn’t sufficient and the posted method isn’t as “over the top” as you claim, but fundamental to not loosing buttons.

Sorry I wasn’t clear about that - my replaced ones have never come off again - it’s the original ones on the shirt which tend to.

[Edit] Note that I am always wearing a shirt, and much of my work is manual/technical, so mine perhaps get knocked off a bit more frequently than others might.

Perfect, I need to move a button on my jacket.

Ok. But now draw the owl.

For the confused: https://www.youtube.com/watch?v=UNPVqbgEUCU

Step 17 looks like a microcosm of me cable managing a PC

“What am I gonna do with all these extra cable bits? Oh right, same thing I do every time, jumble it up and stuff it in the bottom!”

Also, this feels like, unnecessarily complicated. Million dollar idea: button staples. Shoot a couple pointy bits through the diagonal holes, it attaches itself on the back somehow (that’s for engineers to work out, I’m just the idea man), repeat on the other diagonal, bam, button attached.

It has the number of steps it does so that the pressure from the button holding your pants closed is evenly distributed over the fabric (and thread), so that nothing tears or rips. When sewing through cloth more points of attachment is generally better. You might be able to staple a button on without damaging the fabric over time, but it’s probably a lot less comfortable to wear than one sewn on.

Just attached a button to my pants yesterday, after the factory sewn button gave up.

https://www.amazon.com/Buttoneer-Button-Fastening-System-Necessary/dp/B09MR8GZR9

I’m including an Amazon link because I can’t imagine anyone actually following my comment and buying this piece of shit, but if it helps: don’t give Bezos money.

I just bought 2 dozen for my sweatshop 👍👍👍

Now I just need some lawyers to file some post-facto patents Nintendo style and collect my money

Good to know! I was taught as a child because raised female, and its helped more over the years than I thought it would! And repairing rips along seams came up several times!

I still hate threading the needles.

I learned to moisten the eye of the needle instead of the thread. It makes threading a needle way easier. Also, making sure the thread is cleanly cut at the end and not fraying.

Oh they’re always clean cut! I’ll try moistening the needle over the thread next time, but it’s always so finicky.

What a fantastic community I’ve discovered. Thank you for this nugget of knowledge.

Why was I not informed I could have chicken feet symbolism on my shirt buttons??

I’ve had to learn it in middle school and took over an hour to put a thread through the needle